Vinyl Gloves

Vinyl gloves are made from polyvinyl chloride, commonly known as PVC. Commonly, disposable vinyl gloves are made from petroleum.

This is a popular and emerging disposable glove. Certainly, advances in vinyl glove manufacturing technology have improved protective performance, but for now they are suitable for very specific sectors where hazardous materials are not handled as they offer very little protection.

Generally, vinyl gloves are used in the food and beverage industry and are suitable for low-risk tasks where disposable gloves are worn for a short period of time.

The main advantage of vinyl gloves is that they are inexpensive to manufacture and are therefore the cheapest option for the consumer compared to latex and nitrile.

At the same time, disposable vinyl gloves do not contain latex. Of course, while allergic reactions are almost non-existent, many people report that they cause irritation.

While the absence of latex was cited as an advantage, people who use them continue to complain of allergic reactions. In reality, the problem of skin irritation from vinyl gloves is created by the lack of ventilation while wearing them. Unlike other disposable gloves, the hand does not breathe, resulting in sweat and heat being trapped inside the vinyl glove, leading to these irritations that are misinterpreted as allergies .

In addition to poor ventilation, vinyl gloves are also the least elastic , making them less comfortable to wear and less comfortable to wear . This is why it is recommended to wear vinyl gloves for a very short period of time. To be precise, no more than five minutes.

In general, vinyl is the least favorable material for making disposable gloves, and there are many reasons.

- Vinyl is less puncture resistant than nitrile and latex. When vinyl gloves are stretched or bent, the individual molecules separate and the integrity of the protective barrier is compromised.

- It is the least sensitive to touch of all other materials, which makes vinyl gloves unsuitable for tasks that require dexterous handling.

- Vinyl gloves have very low chemical resistance, providing limited protection against chemical and biomedical exposure. They are unsuitable for most organic solvents and water-based solutions.

And amidst all this, as a derivative of petroleum, vinyl gloves have been a red flag for many years by countless environmental organizations for their impact on landfills, as the leaching phenomenon seems to negatively affect the reproduction of fish and other aquatic animals.

Recent research makes vinyl gloves even more dangerous since they are considered mainly responsible for food contamination by phthalates . In short, it has now been proven that the phthalates contained in vinyl and the gloves made from it migrate into food and then release gases into the environment.

Due to their low cost and low levels of protection, vinyl gloves are commonly used in non-hazardous chemical and low-risk infection environments.

Currently, the price per vinyl glove ranges from €0.050 to €0.146 .

Epilogue

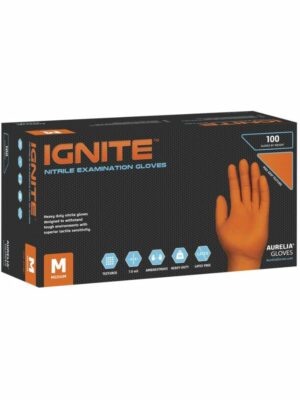

In recent years, nitrile has been by far the most popular choice of disposable gloves in the medical world and most industries. Although they cost a little more, the ever-increasing allergic reactions to latex and the superior chemical and mechanical resistance they offer seem to leave no room for competitors.

So when deciding which disposable glove is right for you, you should ask yourself how much protection you need, from what, and potential allergies. I hope that understanding these key differences between disposable gloves will help you make the right decision.